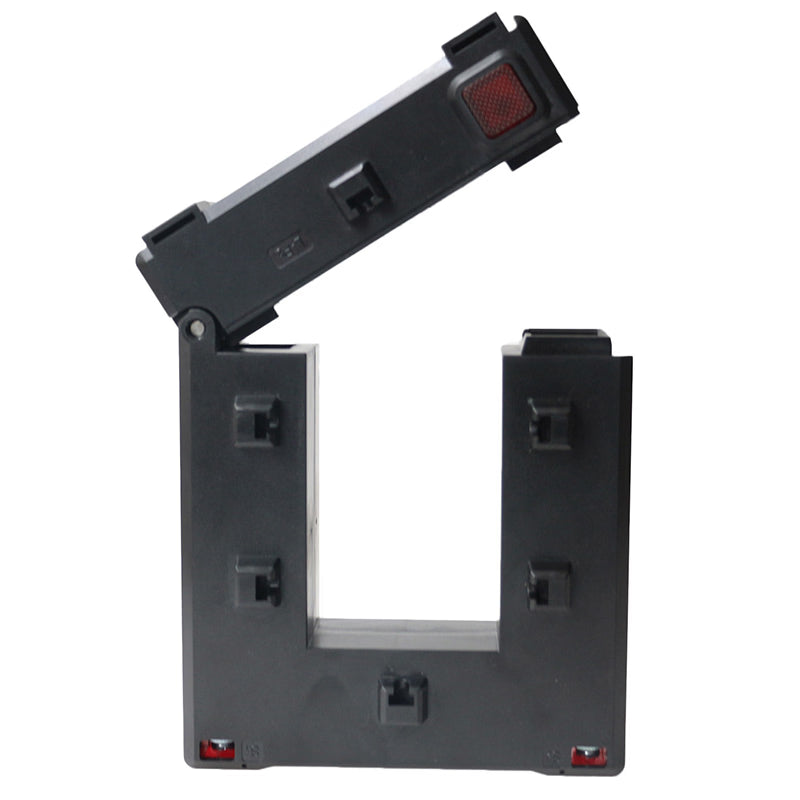

LMHK-612 (60×120 mm Window) Clamp / Split-Core Current Transformer • 4000/5A • Accuracy Class 0.5

Pickup currently not available

Product Description

Overview

The LMHK-612 4000/5A Accuracy Class 0.5 is a high-capacity split-core current transformer, designed for accurate measurement of up to 4000 Amps AC in systems where large conductors or busbars are present. The 60×120 mm window makes it suitable for thick conductors or grouped busbars without requiring disconnection. Accuracy Class 0.5 ensures ±0.5% maximum error under rated conditions—ideal for precision monitoring, energy metering, or power quality tasks.

Key Features

-

Primary Current Rating: 4000 A AC

-

Secondary Current Rating: 5 A AC — gives a 4000:5 ratio

-

Accuracy Class: 0.5 (±0.5%) under rated burden

-

Window / Aperture Size: Approx. 60 × 120 mm — large opening for busbars or large conductors

-

Design: Split-core / clamp-on, allowing retrofit installation or installation without breaking primary conductors

-

Frequency Range: Typically 50 / 60 Hz (HK series)

-

Housing & Material: Flame-retardant plastics, epoxy / PBT internals (based on similar Heyi products) with good insulation and mechanical protection

Additional Specifications (Typical / Expected)

| Specification | Value / Typical |

|---|---|

| Burden (VA) | ~ 15-30 VA typical for 4000/5A in Class 0.5 HK / HK-812 style CTs |

| Measuring Range | Often from ~10% of rated primary up to ~120% without large error (HK-series support) |

| Dielectric / Insulation | Good insulation; likely a dielectric test voltage of ~2.5 kV / 1 minute in many HK-models |

| Operating Temperature | Typically −25 °C to +75 °C (ambient) in Heyi HK models |

| Phase Angle Error | Usually small, ≤ ±30 minutes under rated conditions in HK series CTs |

Use-Case / Applications

-

Industrial switchgear, distribution boards with large busbars drawing high current

-

Power monitoring & metering for large loads (motors, transformer feeders)

-

Energy management systems, power quality analysis, and protection instrumentation

-

Retrofitting mature systems where shutting off or disconnecting primary conductors is problematic

Installation & Safety Notes

-

Ensure that the conductor(s) to pass through the 60×120 mm window fit cleanly, without bending insulation or causing strain

-

Always terminate the secondary circuit to a measurement device or burden; never leave the secondary open with the primary energized — open secondary can lead to dangerously high voltages

-

Secure the clamp fully, ensure mechanical stability, avoid vibration or movement that could shift its position (which can affect accuracy)

-

Install in environment adhering to temperature, humidity, and electromagnetic standards of the spec sheet

-

Follow local electrical safety codes, ensure sufficient insulation, proper wiring, etc.

Benefits

-

Precise measurement with ±0.5% accuracy — good for billing and quality monitoring

-

Large aperture size allows use with large conductors or busbars without disruptive rewiring

-

Clamp/on split-core design simplifies installation and maintenance

-

Robust design suited for industrial environments

Shop Online