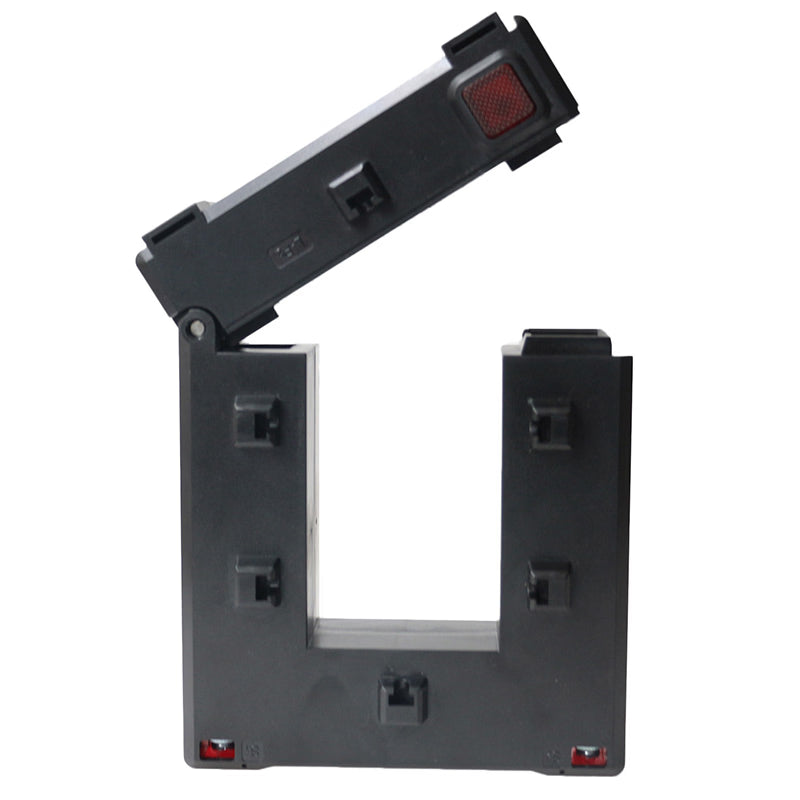

LMHK-612 (60×120 mm Window) Clamp / Split-Core Current Transformer • 3000/5A • Accuracy Class 0.5

Pickup currently not available

Product Description

Overview

The LMHK-612 3000/5A Accuracy Class 0.5 is a high-capacity current transformer designed for heavy electrical systems where precise measurement is needed. With a primary current rating of 3000 A AC and a secondary output of 5 A, coupled with ±0.5% accuracy, this CT is ideal for metering, monitoring, protection, and energy management in large commercial / industrial installations. The large aperture (approx. 60×120 mm) allows it to accommodate oversized conductors or busbars without the need to disconnect them — making installation simpler and less disruptive.

Key Features

-

Primary Current: 3000 A AC

-

Secondary Current: 5 A AC — giving a 3000:5 ratio

-

Accuracy Class: 0.5 (±0.5%) under rated load / within specified burden

-

Window (Inner Aperture) Size: ~ 60 × 120 mm — suitable for large busbars or cable bundles

-

Type / Design: Split-core (clamp-on) style with release / clamp mechanism so it can be installed without shutting down the primary conductor

-

Housing & Materials: Typical HK-series materials — flame-retardant plastics (e.g. PC or similar, often UL94-V0 rated), appropriate core material (silicon steel or equivalent)

-

Frequency Range: Generally 50-400 Hz (per HK-series spec)

-

Operational Temperature Range: Approx. −25°C to +75°C typical for HK models

-

Insulation & Safety: Dielectric strength around 2.5 kV / 1 mA / 1 min (or as per spec), good insulation resistance, moisture protection

Technical Specifications (Expected / Comparable values)

| Specification | Typical / Expected Value |

|---|---|

| Ratio | 3000 : 5 A |

| Accuracy Class | 0.50 (±0.5%) |

| Window Size | ~ 60 mm × 120 mm aperture |

| Burden (VA) | Likely 15 VA for class-0.5 at this level (but verify from manufacturer) |

| Measuring Range | Often 10% In to ~120% In with small error in this class |

| Dielectric Voltage Test | ~2.5 kV AC for 1 minute (common in HK series) |

| Materials | Flame-retardant plastic housing, core of silicon steel, internal support epoxy or PBT bobbin / tie materials |

| Frequency | 50 / 60 Hz standard; spec may allow broader (up to 400 Hz) in some HK series variants |

| Operating Temperature | -25 °C to +75 °C (ambient) |

| Output Terminals / Connections | Usually screw/screw-terminal / clamp type suitable for measurement devices or metering panels |

Applications

-

High current monitoring in large switchgear, transformer feeders, busbars

-

Precision metering / energy management in industrial / commercial power systems

-

Retrofit projects where conductor continuity / uptime is important (split-core design allows installation without disconnecting primary)

-

Use in power quality, monitoring, protection and load balancing systems

Installation & Safety Notes

-

Ensure busbars or conductors fit through the 60×120 mm aperture without bending or damaging insulation

-

Always connect secondary side to a measurement device or burden; never leave secondary open when primary is carrying current

-

Clamp / split-core must be completely closed and secured to avoid measurement error and ensure safety

-

Avoid external magnetic fields or interference that can distort readings

-

Keep away from moisture, extreme temperatures beyond rated spec; ensure adequacy of insulation and enclosure per local electrical codes

Benefits

-

High precision (0.5%) gives reliable readings essential for billing, auditing, or critical monitoring

-

Large aperture allows handling of thick conductors or busbars without system disruption

-

Split-core design enables easier and safer installation and maintenance

-

Built with durable materials and safety features, reducing long term maintenance

Shop Online